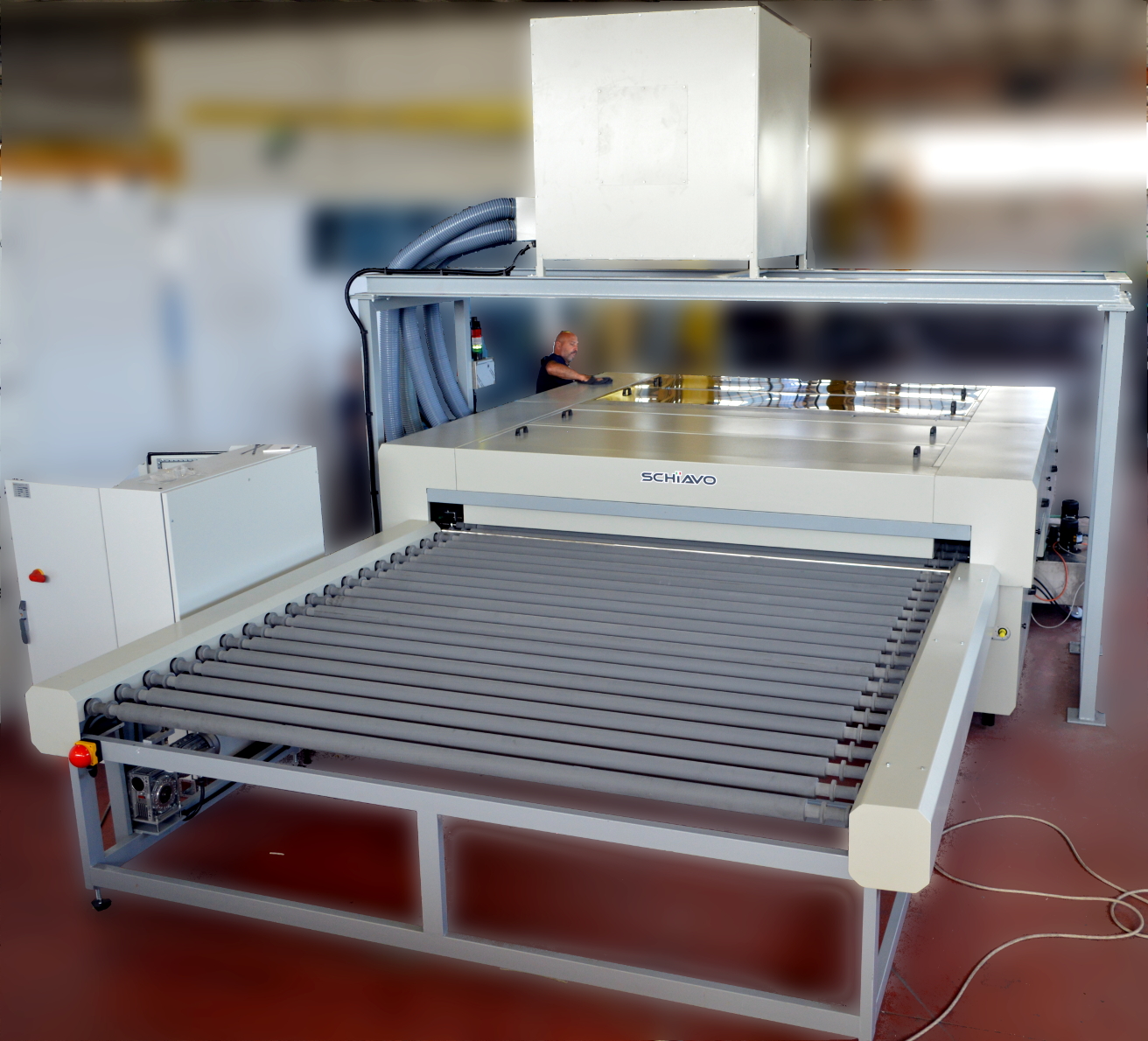

Horizontal Washing Machines HTL series

High-quality horizontal glass washing machines for every purpose.

HTL are the series of horizontal glass washing –and drying machines suitable for the cleaning -and drying of all types of flat glass.

Sturdy and reliable machine, developed to guarantee a long lasting life time.

Suitable for in-line installation with other horizontal machines.

Main features:

Wide use of STAINLESS STEEL «INOX AISI 304»

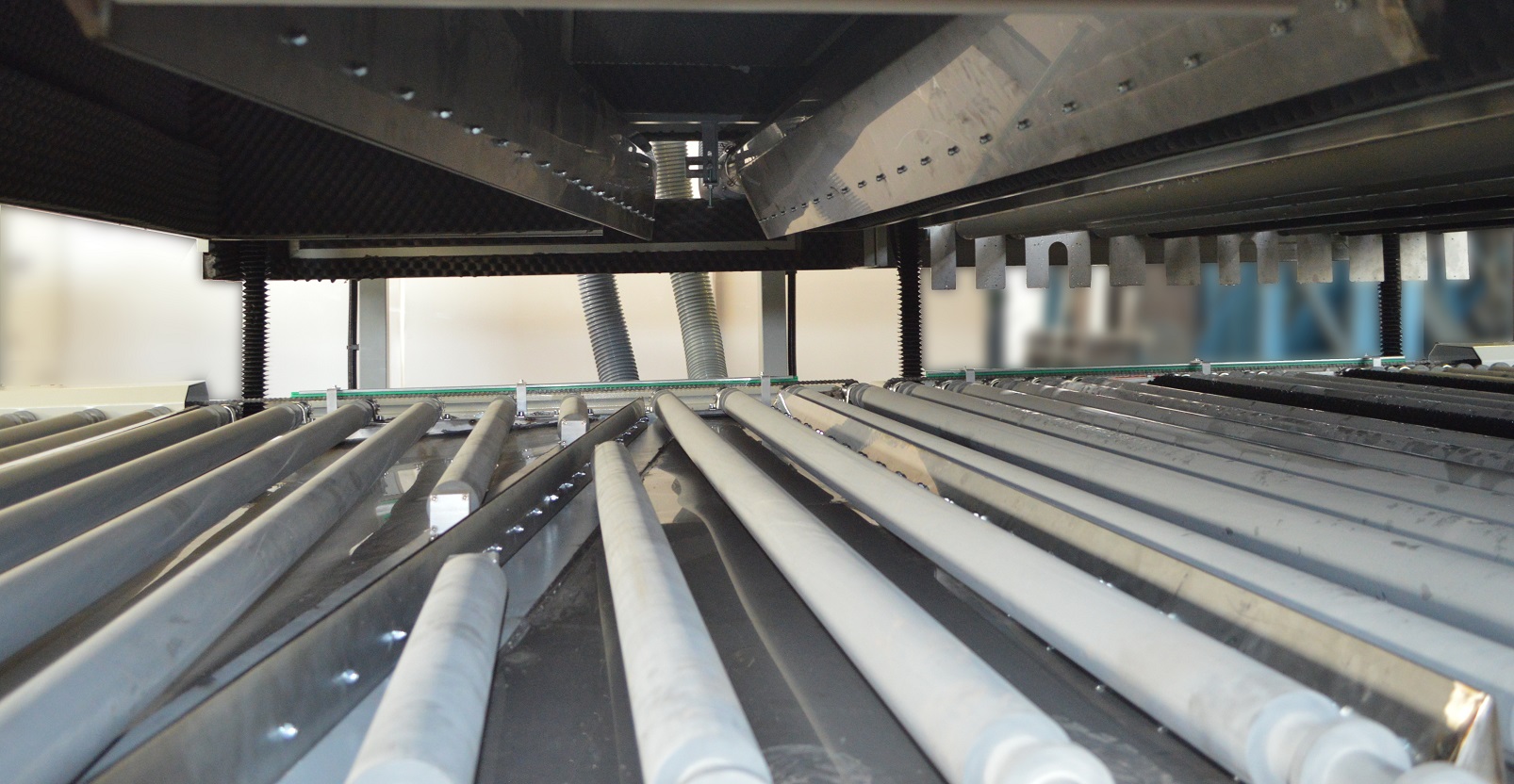

MACHINE BODY, Washing –and Rinsing section made of STAINLESS STEEL «INOX AISI 304»

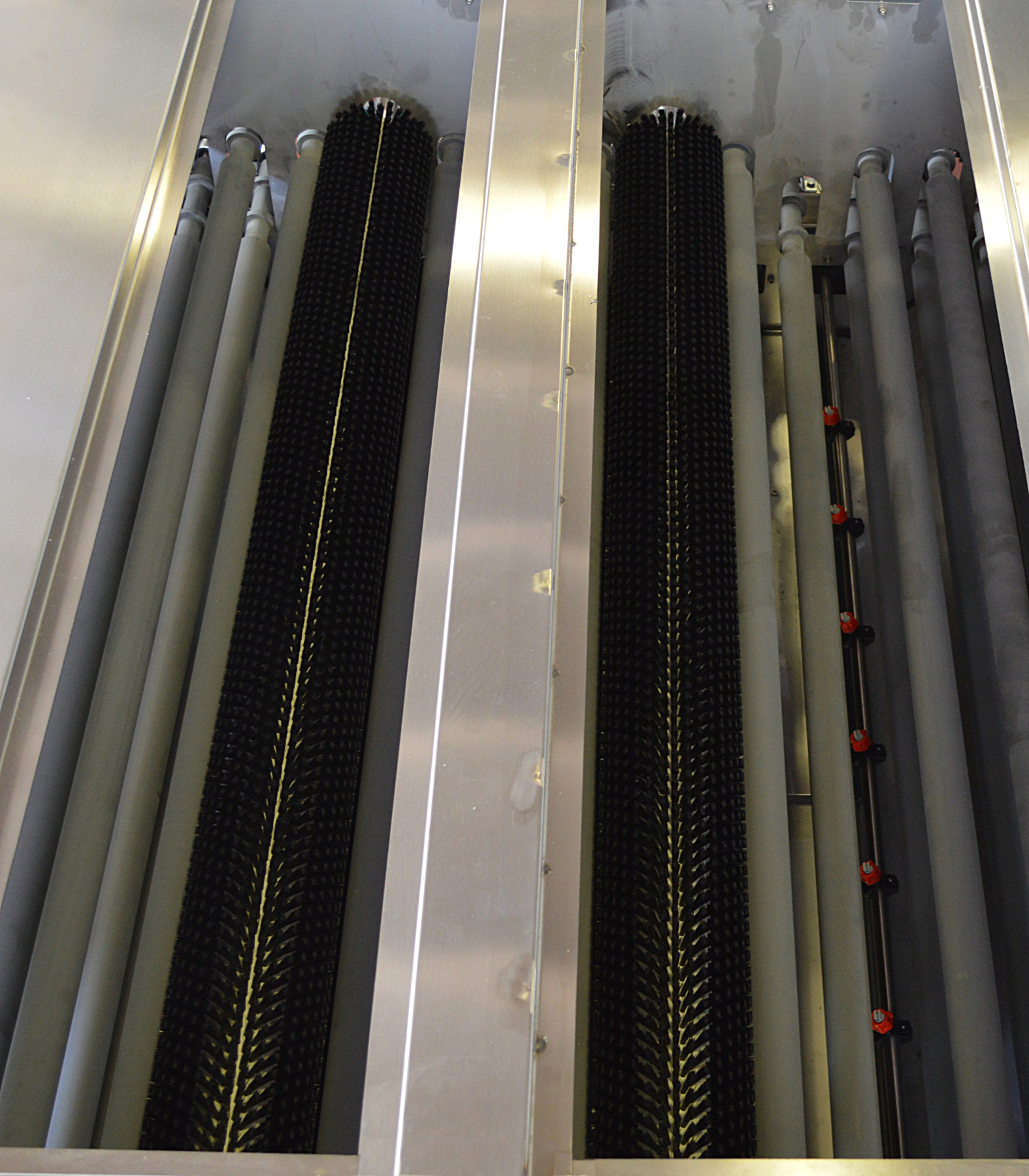

Cylindrical, rectified and balanced nylon brushes with STAINLESS STEEL shafts, made of a single-piece, no sector brushes

STAINLESS STEEL spraying bars

Frames and covers TREATED AGAINST CORROSSION, COLORED WITH EPOXY POWDER PAINT

Air knives made of STAINLESS STEEL «INOX AISI 304»

Mechanical parts in contact with water made of Aluminium, PVC and STAINLESS STEEL

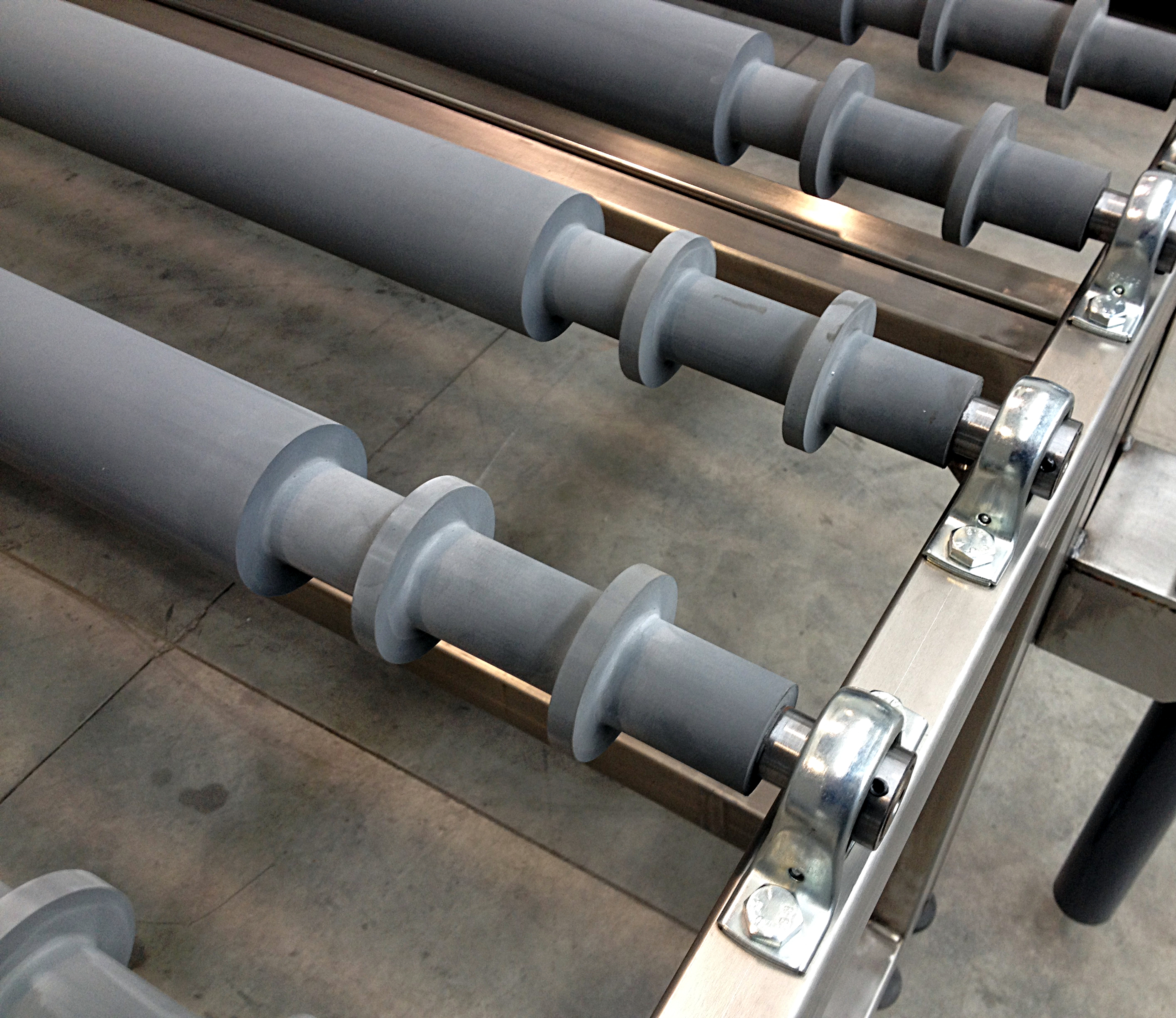

Mechanical parts of transport rollers PROTECTED by means of FIXED RUBBER RINGS

Electronic components of primary TOP BRANDS

WORKING SPEED controlled by INVERTER

Transport rollers made of VULCANISED and RECTIFIED RUBBER ROLLERS

EXTREMELY LOW WATER consumption due to independent recycling flow systems

REDUCED ENERGY consumption (ALL MOTORS IE 3)

VERY LOW maintenance & EASY to use

Machine manufactured by the foreseen CE NORMS

| Model: | HTL500 | HTL1300 | HTL1600 | HTL2000 | HTL2600 | HTL3000 | HTL3300 |

| Max. glass width: | 500 mm | 1300 mm | 1600 mm | 2000 mm | 2600 mm | 3000 mm | 3300 mm |

| Min. glass dim. (LxH): | 150×80 mm / 75×75 mm | 300×200 mm | 400×200 mm | 400×200 mm | 400×200 mm | 450×250 mm | 450×250 mm |

| Thickness: | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * | 3-12 mm / 3-50 mm * |

| Speed: | 1-6 m/min | 1-6 m/min | 1-6 m/min | 1-6 m/min | 1-6 m/min | 1-6 m/min | 1-6 m/min |

| Inlet conveyor: | 500 mm | 1350 mm | 1350 mm | 1850 mm | 2000 mm | 2000 mm | 2500 mm |

| Outlet conveyor: | 500 mm | 1350 mm | 1350 mm | 1850 mm | 2000 mm | 2000 mm | 2500 mm |

| Voltage: | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz |

| Commands Voltage: | 24 V | 24 V | 24 V | 24 V | 24 V | 24 V | 24 V |

| Power: | 5 Kw | 12 Kw | 13 Kw | 20 Kw | 23 Kw | 25 Kw | 29 Kw |

| N° Brushes: | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 |

| Upper Brushes: | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle |

| Lower Brushes: | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle | 0.3 µm Bristle |

| N° Air Knives: | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| N° Water tanks: | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 |

| Ø Brushes: | 90 / 120 mm | 150 mm | 150 mm | 190 mm | 190 mm | 190 mm | 190 mm |

| Overall Dimensions: | 1500x800xh900 mm | 6100x1800x2900 mm | 6500x2300xh3400 mm | 7200x3500x3000 mm | 7500x3700xh3000 mm | 7500x4100x3000 mm | 8500x4400xh3000 mm |